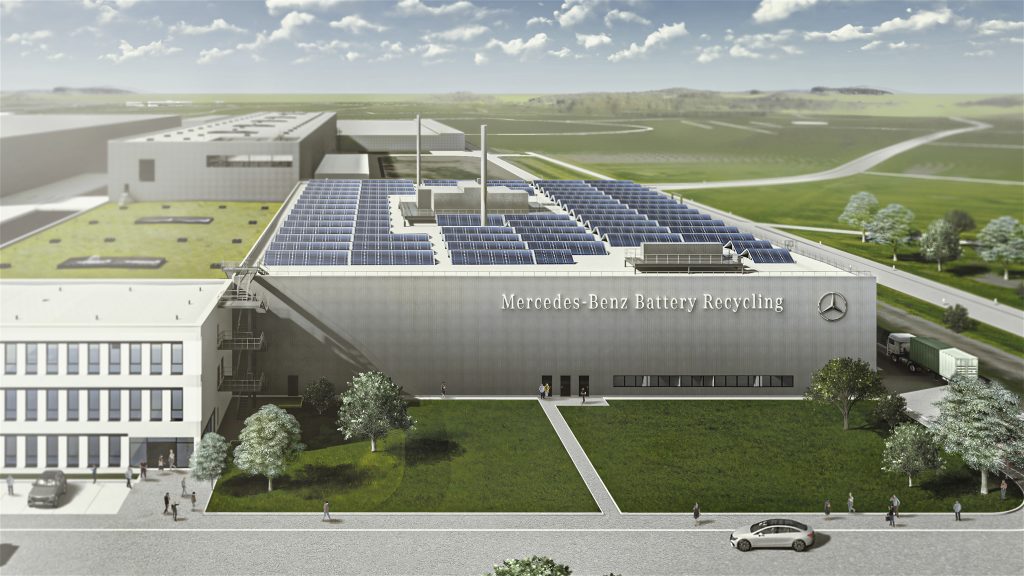

Mercedes-Benz has announced the groundbreaking ceremony for its new battery recycling factory in Kuppenheim, Germany, which will establish closed-loop recycling of battery raw materials and cut resource consumption.

First Stage

The plant’s first stage, the mechanical dismantling of electric vehicle batteries, is scheduled to commence by the end of this year, followed by the establishment of a hydrometallurgy pilot plant subject to the outcome of discussions with the public sector. This integrated recycling concept within a single factory is currently unique in Europe.

Budget

Mercedes is pouring a “double-digit million Euro” into the construction of the battery recycling plant, which comes from the coffers of the German Federal Ministry of Economics and Climate Protection as an inclusion of its scientific research project. The pilot plant is projected to have a capacity of 2,500 tonnes annually and a recovery rate of more than 96 percent. The recovered materials will be fed back into the recycling loop to generate over 50,000 battery modules for new Mercedes EVs.

Benefits

The Mercedes-Benz battery recycling factory in Kuppenheim is expected to bring several benefits to the automaker, the community, and the environment.

First, the recycling plant will aid Mercedes in reducing its dependence on primary raw materials, such as lithium, cobalt, and nickel. By recycling the materials from old batteries, the company can create a circular economy for battery materials and reduce the amount of waste generated by the production of new batteries. This will also help the automaker secure a sustainable supply of raw materials for its electric vehicles.

Second, the pilot plant will support Mercedes’ aim to establish expertise in the field of circular economy, which will be an important competitive advantage in the growing electric vehicle market. The automaker will be able to offer customers a more sustainable and environmentally-friendly product, which could help it attract new customers who are concerned about the environmental impact of their purchases.

In addition, the battery recycling factory will create new jobs and support the local economy. The factory will require skilled workers to operate and maintain the equipment, as well as logistics professionals to manage the transportation of materials.

From an environmental perspective, the project will help reduce the carbon footprint of Mercedes’ electric vehicles by reducing the amount of raw materials needed to produce new batteries. The recycling process will also aid in the reduction of the amount of waste generated by the production of new batteries, which can have a significant environmental impact.

Moreover, the recycling plant will lessen the number of batteries that end up in landfills or incineration facilities, which can cause environmental damage and pose a risk to public health. By recycling the materials from old batteries, the plant will reduce the need for new mining activities, which can cause significant environmental damage and contribute to climate change.

Conclusion

Overall, the Mercedes-Benz battery recycling factory in Kuppenheim is expected to bring significant benefits for the automaker and the environment, helping the German marque establish expertise in circular economy, reduce its dependence on primary raw materials, create new jobs, and reduce the environmental impact of its electric vehicles.