Mercedes-Benz Embraces “Digital First” Approach In Car Production

Giancarlo Perlas September 21, 2023In an era defined by technological advancement, Mercedes-Benz is boldly stepping into the future with its “Digital First” approach to production. This pioneering shift promises to usher in a new era of manufacturing efficiency and innovation, setting the stage for a more flexible and intelligent Mercedes MO360 production system.

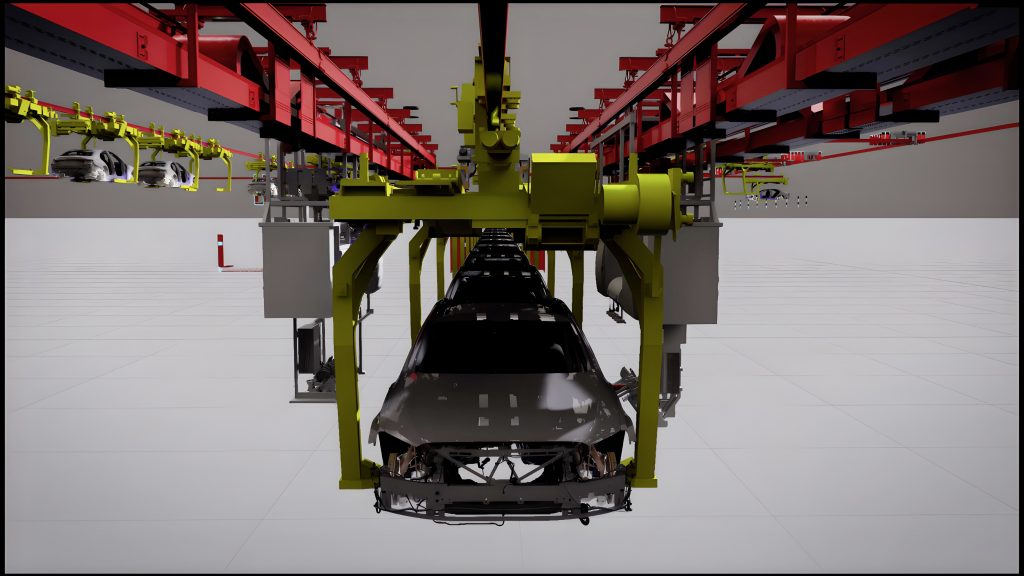

The Power of Digital Twins

According to an official press release, central to Mercedes-Benz’s transformation are digital twins—virtual replicas of real-world manufacturing environments. These digital doppelgangers are not mere novelties but critical tools used with precision at Mercedes factories in Rastatt (Germany), Kecskemét (Hungary), and Beijing (China).

These simulate, fine-tune, and optimize assembly lines, ensuring that the transition to next-generation vehicles is seamless and efficient.

Mercedes Modular Architecture (MMA): A Game Changer

The Mercedes-Benz Modular Architecture (MMA) represents a paradigm shift in production. This adaptable system allows the simultaneous manufacturing of electric, hybrid, and combustion models on a single assembly line.

The concept was unveiled at the Munich IAA MOBILITY, underscoring the automaker’s commitment to sustainability and adaptability to evolving market demands.

AI-Driven Efficiency

Harnessing artificial intelligence (AI) is another area where Mercedes-Benz shines. Particularly noteworthy is its application in energy-intensive paint shops, where AI takes on the role of monitoring and optimizing sub-processes within topcoat booths.

This AI-driven approach achieves a remarkable 20% reduction in energy consumption while streamlining production processes, significantly reducing task initiation times.

Democratizing Data with ChatGPT

In May, Mercedes-Benz introduced a groundbreaking project within its MO360 digital ecosystem, democratizing data access across the organization. This initiative empowers employees with real-time access to vital production data, fostering quicker decision-making and defect identification.

The result is enhanced transparency and seamless collaboration throughout the production network.

Mercedes-Benz Operating System (MB.OS): A Centralized Approach

Moreover, the implementation of the Mercedes-Benz Operating System (MB.OS) signifies a pivotal moment in vehicle production. This system centralizes software operations, ensuring rapid, synchronized software updates.

With a chip-to-cloud architecture, every Mercedes vehicle leaving the production line is guaranteed to be “always up-to-date.” Integration with the Mercedes Intelligent Cloud (MIC) enables swift global software rollout, elevating vehicle safety and quality standards.

Mercedes-Benz’s Vision for the Future

Underlying the luxury vehicle maker’s transformative journey is a visionary perspective articulated by Jan Brecht, Chief Information Officer (CIO) of Mercedes-Benz Group AG. Brecht envisions a future where trust in digital twins rivals that in physical reality—a testament to the company’s unwavering commitment to embracing digitalization and cutting-edge technologies.

Through strategic partnerships with industry leaders like NVIDIA and the deployment of innovative solutions, Mercedes is poised to redefine the automotive manufacturing landscape.

Final Thoughts

Mercedes-Benz stands at the vanguard of automotive innovation, skillfully weaving technology into the fabric of its production processes. By embracing the “Digital First” paradigm, deploying digital twins, and tapping into AI-driven efficiency, the automaker is laying a solid foundation for a manufacturing ecosystem that is agile, sustainable, and highly responsive to evolving market dynamics.