Mercedes-Benz TecDay – Occupant protection

Muamer Hodzic November 12, 2008Â

With the new E-Class, Mercedes has created another masterpiece of passenger-car safety technology. The saloon’s front deformation zone works on several levels – making it even more effective as the impact forces are distributed over a wide area and can be made to bypass the passenger cell, With seven airbags fitted as standard, not to mention seat-belt tensioners, belt force limiters and NECK-PRO crash-responsive head restraints, the new E-Class offers an even more extensive package of safety equipment than its predecessor. Adaptive belt force limiters will be installed in the rear for the first time

The pioneering work carried out by B©la Bar©nyi enabled Mercedes-Benz to develop the basic principles of passenger-car safety in the 1940s and 1950s. And these principles still apply to this day. Bar©nyi’s ideas first came to fruition in the “Ponton” (three-box body) Mercedes (model series W 120) exactly 55 years ago in autumn 1953. This precursor to the E-Class was the world’s first car to feature a crash-stable floor assembly, which enhanced occupant safety in the event of a frontal or side impact.

This car’s successor – model series W 110/111/112 with the distinctive tail fins – provided the next milestone in the field of safety technology. From 1959 onwards, these saloons were the first models into which Mercedes-Benz incorporated front and rear crumple zones. In the event of an accident, these zones absorb energy in a predetermined manner and distribute the impact forces, thus greatly reducing the forces exerted on the occupants.

This Mercedes concept for the safety body still forms the basis for passive

safety today; it is part of all modern-day passenger cars, not just those made by Mercedes-Benz.

B©la Bar©nyi’s successors at the Mercedes-Benz Technology Centre in Sindel-fingen have continued to further develop the concepts devised by their mentor, based on the latest development and calculation methods and the use of state-of-the-art bodyshell materials. The extent of their dedication has reached a new

pinnacle with the new E-Class. During the course of its several years of development to date, the saloon has successfully come through over 150 crash tests and more than 17,000 realistic crash test simulations, including around

40 different crash tests which the saloon had to pass in order to gain world-wide approval and nine extremely demanding, in-house impact tests, some of which go well beyond the statutory requirements. Only cars that pass these tests receive the highest accolade in automotive safety: the Mercedes star.

The results of the crash tests prove that Mercedes has pulled off yet another masterstroke in the field of occupant safety.

Large deformation zones are capable of absorbing high forces in the event of an accident

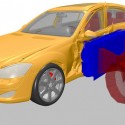

Compared to the previous model series, the Mercedes engineers have enlarged the deformation zones substantially in the front and rear sections as well as improving the energy flows. The front crumple zone has four independently acting impact levels, meaning that the forces can be distributed over a wide area while bypassing the passenger cell.

1) Sectional panels above the wheel arches form the upper side-member level. From here, the impact forces are channelled into the A-pillars and, subsequently, into the roof frame.

2) An aluminium crossmember connects the forward-extended side members and ensures that the forces are transferred to the side facing away from the impact. The crossmember and the forward-extended side members form the central impact zone.

3) The integral support to which the engine, steering and front axle are attached also serves as an impact level in the event of a frontal collision. It is made of high-strength steel and has been connected to the newly developed floor side members by means of special supporting tubes. As a consequence, the integral support can deform in a predetermined manner and absorb energy in the event of a crash on the one hand and channel high impact forces straight into the vehicle floor on the other.

4) The side skirts have been extended forwards to support the wheel and prevent it from entering the footwell in the event of an offset frontal collision. This design also allows the wheel to absorb some of the crash energy. In order to provide specifically targeted front-wheel support and location, Mercedes-Benz has also developed special struts and additional energy-absorbing elements in the wheel arches. The struts are arranged diagonally and prevent the passenger cell from sinking in the event of an impact.

The firewall is a four-part construction. This design enables Mercedes engineers to vary the material thickness according to the level of vulnerability in an accident. As the load acting on the firewall during a frontal crash is greatest in the lower section, the sheet steel used here is more than twice as thick.

Around 72 percent of all the body parts are made from high-strength steel

Key aspects of the safety concept at the heart of the new E-Class include intelligent design and meticulous material selection. More so than ever before, Mercedes-Benz has given preference to ultra-high-strength steel alloys because they offer maximum strength whilst minimising weight and, therefore, are essential for meeting strict Mercedes safety and durability requirements. Around 72 percent of all the bodyshell panels for the new E-Class are made from these grades of steel – a new record in passenger-car development. These ultra-high-strength, high-tech alloys, which boast three to four times the tensile strength of conventional steel grades, account for around eight percent of the weight. They are used at points where the material can be subjected to very high stresses during an accident – as a material for the B-pillars and roof frame to provide side impact protection, for example, or at the rear to produce a robust crossmember.

If these sophisticated alloys were not used, far more material would be required in order to meet the stringent safety requirements. The B-pillar is a perfect case in point: the body components which have to absorb high forces and transfer these to the body structure in the event of a side impact consist of sheet-metal shells plus an extensive reinforcement which reaches as far as the upper edge of the belt deflector. One of the shells and the reinforcement are made from ultra-high-strength, hot-formed steel. Were they made using conventional sheet steel, however, the B-pillars would be more than a third heavier. In other words, the ultra-high-strength, high-tech alloy enhances safety whilst also reducing weight.

Custom-designed floor panels form the robust backbone of the passenger cell

The passenger cell of the new E-Class proves to be a structure which is virtually immune to deformation and which keeps the passengers’ survival space intact, even at high impact speeds, regardless of whether the collision is head-on, from the rear or from the side, or whether the vehicle rolls over. The use of high-strength steel and thicker panels plays as important a role here as the installation of additional load-bearing members.

The main floor assembly consists of different sheet-metal plates that either

undergo flexible rolling or are welded together by laser beam and subsequently shaped. Flexible means that the ultra-high-strength steel can be processed in such a way that areas with different steel thicknesses can be produced within a single component. The middle blank forms the tunnel – the actual backbone of the passenger cell. Here the thickness of the custom-designed panels varies between 1.4 and 2.0 millimetres, depending on the stresses and loads to which they are subjected.

Other new features which are very important for both occupant protection and the rigidity of the bodyshell include the continuous floor side members, the insides of which are further reinforced with extra sections. Their front faces connect to the side members, thereby lengthening the load-bearing paths along which forces can be distributed in the event of an impact. At the rear, the floor side members extend as far as the crossmember beneath the rear seat unit to stabilise the entire floor structure.

The Mercedes engineers have also incorporated sturdy aluminium transverse sections – known as transmission tunnel braces – into the floor assembly. One is located beneath the transmission, and is designed to direct forces to the opposite side of the vehicle during a lateral impact. The second creates a connection between the two side members. It likewise braces the floor assembly and is able to channel impact forces into the floor structure at an early stage in the event of a side-on collision.

The rear structure has successfully passed the toughest of crash tests

Multi-piece side members and a robust, flexible crossmember made from ultra-high-strength steel form the key components of the rear-end structure. The rear side members are continuous, closed box sections with carefully graduated material thicknesses. These are able to absorb high forces, thereby making a decisive contribution to occupant safety in the event of a rear impact. The bolt-on flexible crossmember is manufactured using a flexible rolling process which likewise allows the material thickness to be varied as required. Accordingly, the material thickness on the outside of the crossmember – where impact loads are highest – is greater than on the inside.

The new E-Class also meets the world’s most stringent crash regulations where rear impact protection is concerned, for example the 80-km/h test in the US.

The restraint system for the E-Class includes seven airbags as standard

With seven airbags fitted as standard, not to mention seat-belt tensioners, belt-force limiters and NECK-PRO crash-responsive head restraints, the new E-Class offers an even more extensive package of safety equipment than its predecessor. The airbags, which deploy in a matter of milliseconds in the event of an accident, include two adaptive airbags (for the driver and front passenger), a kneebag for the driver, two sidebags in the front-seat backrests and two large windowbags which extend from the A-pillar to the C-pillar during a side impact. Rear sidebags can be ordered as optional extras.

Three-point inertia-reel seat belts with belt tensioners and belt-force limiters are fitted as standard for the driver, the front passenger and the occupants of the

outer seats in the rear. Force limitation is performed on an adaptive basis in the front: after reaching a certain maximum retention, the belt force is reduced to a lower level – the belts are allowed to slacken so that the occupants can sink deeper into the airbags as they deploy, reducing the strain exerted on the torso.

Rear belt-force limiters that adapt to the size of the passengers

From autumn 2009, Mercedes-Benz will be offering adaptive belt-force limiters for the rear seats as an option for the first time. These belt-force limiters adapt to the size of the rear passengers automatically. The newly developed system detects whether the rear occupant is large or small as soon as the seat belt is put on, based on the length of the pulled-out seat belt, and adapts its mode of operation accordingly. The maximum restraint force is activated immediately if the rear passenger is large in size. Only once a certain time has elapsed does the limiter reduce the force. In the case of smaller occupants, the force exerted by the belt is set to a lower level and is not increased continuously until the crash is actually taking place. Hence the protective effect of the seat belt can be adjusted, i.e. further optimised, in line with the occupant’s body size.

Crash-responsive head restraints reduce the risk of whiplash injuries

NECK-PRO is the name Mercedes-Benz has given to a crash-responsive head restraint whose development, like that of PRE-SAFE®and other Mercedes innovations, is based on analyses of real accidents. NECK-PRO is an effective means of reducing the risk of whiplash injuries during a rear-end collision. If the sensor system detects a rear-end collision with a defined impact severity, it releases pre-tensioned springs inside the head restraints, causing the head restraints to move forward by about 40 millimetres and upwards by 30 millimetres within a matter of milliseconds. This means that the heads of the driver and front passenger are supported at an early stage.

|

Â

|

Front seats

|

Rear seats

|

|

Inertia-reel seat belts with height adjustment

|

x

|

· Height adjustment for the outer seats

|

|

Belt tensioners

|

x

|

· for the outer seats

|

|

Belt-force limiters

|

· with adaptive control

|

· with optional adaptive control for the outer seats from autumn 2009

|

|

Head restraints

|

· with NECK-PRO function

|

x

|

|

Front airbags, two-stage

|

x

|

Â

|

|

Sidebags

|

x

|

optional

|

|

Windowbags

|

x

|

x

|

|

Kneebag

|

· on the driver’s side

|

Â

|

Comments (4)