Mercedes-Benz launches BLUETEC initiative in Europe

Muamer Hodzic August 10, 2007

On the back of positive experiences gained in the American market since the autumn of 2006, the environment-compatible BLUETEC diesel system is now also available in a passenger car model in the European market. Mercedes-Benz has achieved a massive reduction in emissions and compliance with the EU 5 standard whilst retaining the same favourable consumption figures. Thanks to the intelligent BLUETEC technology, this compression-ignition engine is one of the world’s cleanest and most efficient drive trains.

While it is unfortunate that Volkswagen and BMW have left the co-operation with Mercedes, it is quite understand on why they did it. The BLUETEC term has been used for quite sometime to descibe Mercedes-Benz cars, using the same term to describe a clean buring BMW diesel wouldn’t make the BMW owners happy.

Press Release

Environmental compatibility, driving pleasure and comfort are among the strengths of the new E 300 BLUETEC, with which Mercedes-Benz is launching its BLUETEC initiative in Europe. Based on the proven CDI models, this E-Class boasts cutting-edge emissions management and excellent ecological, economical and dynamic characteristics. The 3.0-litre V6 engine developing 155 kW/211 hp and an imposing 540 Nm of torque burns just 7.3 litres* of diesel per 100 kilometres and its emissions levels already fulfil future Euro stipulations. The E 300 BLUETEC accelerates from 0 to 100 km/h in 7.2 seconds* and is capable of a top speed of 244 km/h*. At the same time, the BLUETEC model – like all its E-Class stable-mates – combines the suspension comfort typical of Mercedes with the proverbial “feel-good” ambience in the interior and outstanding safety standards.

The BLUETEC technology developed by DaimlerChrysler does an excellent job of reducing diesel vehicle emissions, in particular nitrogen oxides. To this end, the engineers at the Mercedes-Benz Technology Centre pursue various strategies. For example, in an initial step the formation of nitrogen oxides in the E 300 BLUETEC has been reduced through optimisation measures inside the engine.

* provisional data

Among the other measures employed are:

* A reduction in the compression ratio to 16.5:1

* The use of special piezo injectors with reduced hydraulic flow

* An optimised exhaust gas turbocharger with variable turbine geometry

* Optimised exhaust gas recirculation control with raised return rate

* The use of ceramic glow plugs, which ensure quick cold starts every time for reduced-compression engines

Complementing the revisions carried out inside the engine is an efficient exhaust gas treatment system tailored specially to the E 320 BLUETEC powerplant. This includes the oxidation catalytic converter – which cuts emissions of carbon monoxide (CO) and unburned hydrocarbons (HC) – and an additive-free diesel particulate filter. A further developed NOx storage catalytic converter with a patented onboard ammonia generation system teams up with an SCR catalytic converter and enables extremely low nitrogen oxide emissions. This exhaust gas treatment system works without the need for any additional equipment.

BLUETEC initiative already seeing success

Mercedes-Benz first launched its BLUETEC initiative for passenger cars in the USA. It was here that the E 320 BLUETEC was launched onto the market in October 2006 as the world’s only passenger car to be fitted with this technology. And Mercedes-Benz is set to offer another three V6 BLUETEC models in the US – from the GL, M and R-Class ranges – from 2008. International automotive journalists have been among those to acknowledge the brand’s ongoing commitment to this technology, voting the E 320 BLUETEC “2007 World Green Car”. The members of the jury from 22 countries praised BLUETEC as a pacesetter for new and extremely clean diesel technology.

BLUETEC is also in use in commercial vehicles. Indeed, the technology has been proving its mettle here since 2005 and is now available for all commercial vehicle model series. DaimlerChrysler has already delivered over 60,000 Mercedes-Benz trucks and buses with this pioneering emissions-reducing system.

BLUETEC – a building block in the reduction of CO2

In the ongoing debate on current and future emissions standards for vehicles, one frequently overlooked fact is that carbon dioxide (CO2) emissions are not covered by conventional exhaust emissions limits. A car’s CO2 emissions are directly linked to fuel consumption. A reading such as 140 g CO2/km, for example, is nothing other than an alternative fuel consumption figure, equating to fuel consumption of around 5.3 l/100 km in diesel engines or 5.9 l/100 km for petrol models. The same figure would also be recorded by equivalent cars which pumped out their exhaust gases into the environment unfiltered – i.e. without being treated though catalytic converters or systems minimising particulate output.

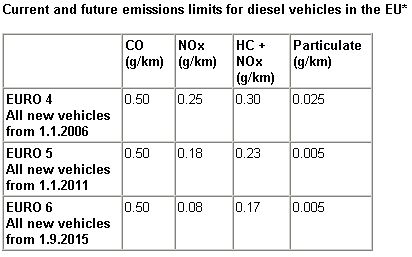

In contrast to CO2 emissions, exhaust components like nitrogen oxide, carbon monoxide, hydrocarbons and combustion residue in the form of particulates can all be reduced through exhaust gas treatment – in some cases to the point where they are barely detectable. This is where the innovative, modular exhaust gas purification system BLUETEC comes into its own. BLUETEC gives diesel vehicles the technology they need to operate in an environment-friendly way and will meet the planned emissions limits of the future as well. In addition to the E 300 BLUETEC, all future BLUETEC models will satisfy the Euro 5 standard due to come into force in 2011. BLUETEC thus represents an important building block in the reduction of CO2 emissions.

Comments (1)